O-Ring Range

O-rings are among the most straightforward yet essential sealing solutions, known for their affordability, ease of installation, and dependable performance across countless industries. Our extensive range includes nitrile, Viton, and silicone O-rings, available in both metric and imperial sizes to meet the diverse needs of various applications. Designed to withstand different temperatures, chemicals, and pressures, our O-rings offer reliable sealing solutions for automotive, industrial, aerospace, and household applications. Whatever your project demands, you’ll find a durable, high-quality O-ring to ensure a secure and lasting sea

View our o-ring ranges by material type:

-

Nitrile O-Rings

View rangeOur extensive range of nitrile o-rings include metric, imperial and hozelock sizes suitable for most applications. Delivering top resistance and performance across industries, our O-rings come in various shore hardnesses, specialist compounds, and metric or imperial sizes. Made from nitrile, they withstand chemicals, temperatures from -40°C to +108°C, and are suitable for aeronautical and nuclear applications.

-

Viton O-Rings

View rangeWe also offer a wide range of highly chemically resistant viton o-rings, available in varying sizes and dimensions. Crafted from a synthetic rubber that resists petrol, solvents, strong chemicals, and hydrocarbons, our Viton O-Rings excel in automotive and aerospace applications. Withstanding fuel, they’re ideal for combustion engines and come in a variety of internal and external dimensions to suit most needs.

-

Silicone O-Rings

View rangeOur range of silicone o-rings are suitable for both freezing and extremely hot environments, and come in various sizes. Highly versatile and durable, our silicone O-rings withstand extreme temperatures and offer strong sealing for diverse applications—from household items to automotive parts. Totally Seals provides a wide range of quality silicone O-rings in various internal and external diameters to suit most needs.

Know what you want? Search our store:

Browse our full o-ring range:

-

30mm x 3mm (36mm OD) FKM (Viton™) O-Rings

Regular price From £8.49 GBPRegular priceUnit price / per -

35mm x 3mm (41mm OD) Silicone O-Rings

Regular price From £8.74 GBPRegular priceUnit price / per -

35mm x 3mm (41mm OD) FKM (Viton™) O-Rings

Regular price From £8.74 GBPRegular priceUnit price / per -

35mm x 1.5mm (38mm OD) Nitrile O-Rings

Regular price From £8.86 GBPRegular priceUnit price / per -

40mm x 3mm (46mm OD) Silicone O-Rings

Regular price From £8.86 GBPRegular priceUnit price / per -

40mm x 3mm (46mm OD) FKM (Viton™) O-Rings

Regular price From £8.86 GBPRegular priceUnit price / per -

40mm x 1.5mm (43mm OD) Nitrile O-Rings

Regular price From £9.11 GBPRegular priceUnit price / per -

45mm x 2mm (49mm OD) Nitrile O-Rings

Regular price From £9.75 GBPRegular priceUnit price / per -

45mm x 2.5mm (50mm OD) Nitrile O-Rings

Regular price From £9.75 GBPRegular priceUnit price / per -

50mm x 2mm (54mm OD) Nitrile O-Rings

Regular price From £10.12 GBPRegular priceUnit price / per -

50mm x 2.5mm (55mm OD) Nitrile O-Rings

Regular price From £10.37 GBPRegular priceUnit price / per

What are o-rings?

O-Rings, also known as packing seals, are mechanical gaskets created in the shape of an O, which can be placed into a groove and compressed between two or more parts. They were first brought to market way back at the dawn of the 20th century, and even after 120 years of engineering, manufacturing and component innovations o-rings have stayed more or less identical in both form and function.

The materials used in the manufacture of o-rings have become more high-tech over time, but at its core, o-rings remain the beautifully straightforward and reliable solution to a problem that was first brought up more than a century ago.

How do o-rings work?

O-rings work by creating a tight seal between two surfaces, preventing the passage of gases or liquids. When an O-ring is compressed between two surfaces, it deforms to fill any gaps, creating a secure seal. This deformation exerts pressure on the surfaces, effectively blocking any fluid or gas from leaking through. Made from flexible, resilient materials, O-rings maintain their shape and sealing properties under pressure, temperature fluctuations, and exposure to various chemicals, making them essential in numerous industrial and mechanical applications.

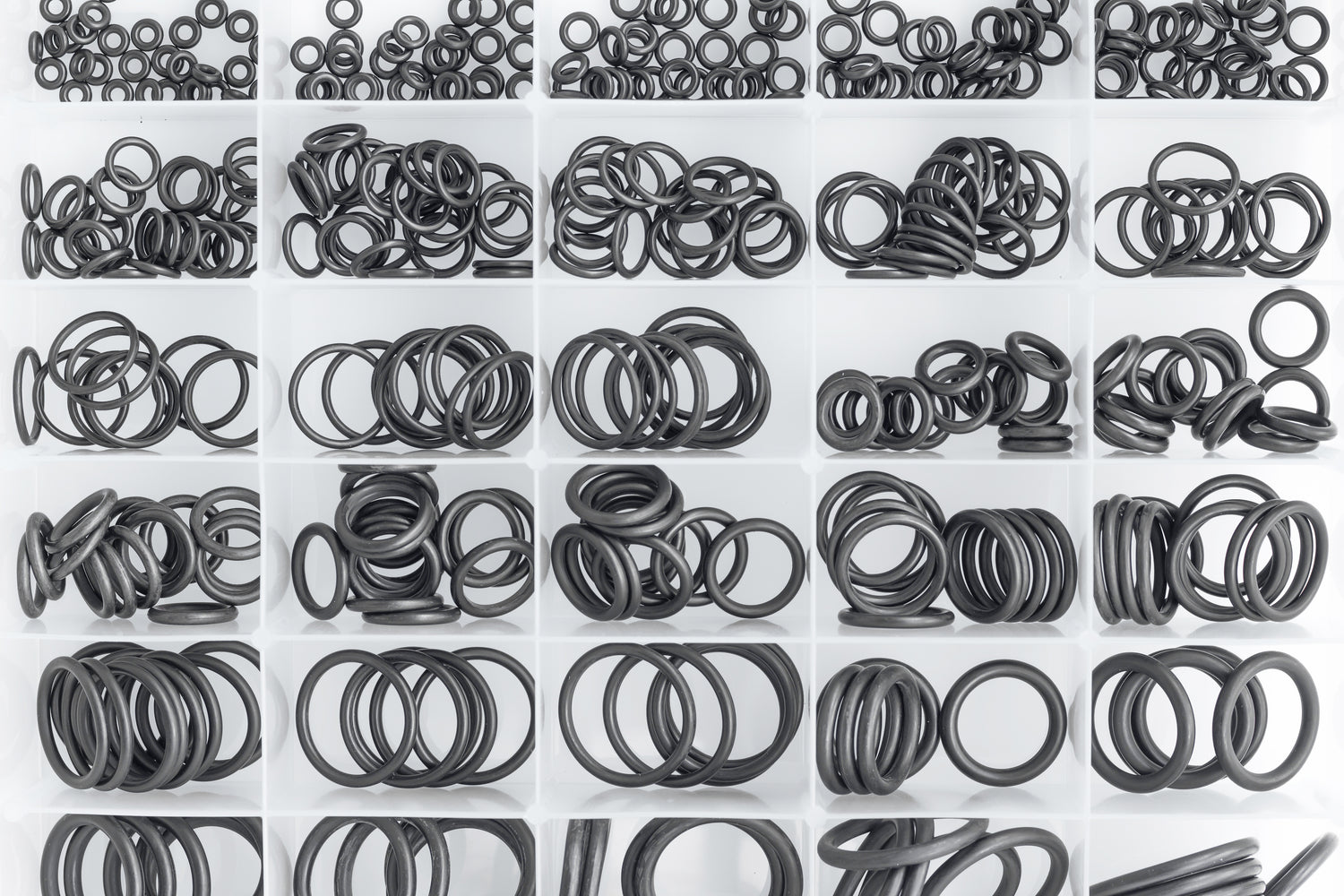

What are the main types of o-rings?

The main types of O-rings are categorised by their material, each suited to specific applications and environments:

- Nitrile (NBR) O-Rings: Known for excellent resistance to oils, fuels, and certain chemicals, nitrile O-rings are widely used in automotive, industrial, and aeronautical applications. They perform well in temperatures from -40°C to +108°C.

- Viton (FKM) O-Rings: Highly resistant to chemicals, heat, and hydrocarbons, Viton O-rings are ideal for applications in the automotive and aerospace industries. They withstand extreme temperatures and exposure to solvents, making them suitable for fuel and engine systems.

- Silicone O-Rings: With high flexibility and durability in extreme temperatures, silicone O-rings are often used in medical, food processing, and household applications. They offer excellent sealing in low and high temperatures but are less resistant to fuels and oils.

- EPDM O-Rings: Resistant to water, steam, and weathering, EPDM O-rings are commonly used in plumbing, outdoor, and HVAC applications. However, they are not suitable for oil or fuel exposure.

- PTFE (Teflon) O-Rings: These provide excellent chemical resistance and can endure high temperatures, but they are less flexible than rubber O-rings. PTFE O-rings are commonly used in harsh chemical environments and high-temperature applications.

- Neoprene O-Rings: Known for good weather and ozone resistance, neoprene O-rings are often used in refrigeration, air conditioning, and electrical applications.

Each type offers specific properties tailored to various industrial needs, helping ensure reliable performance and long-lasting seals.

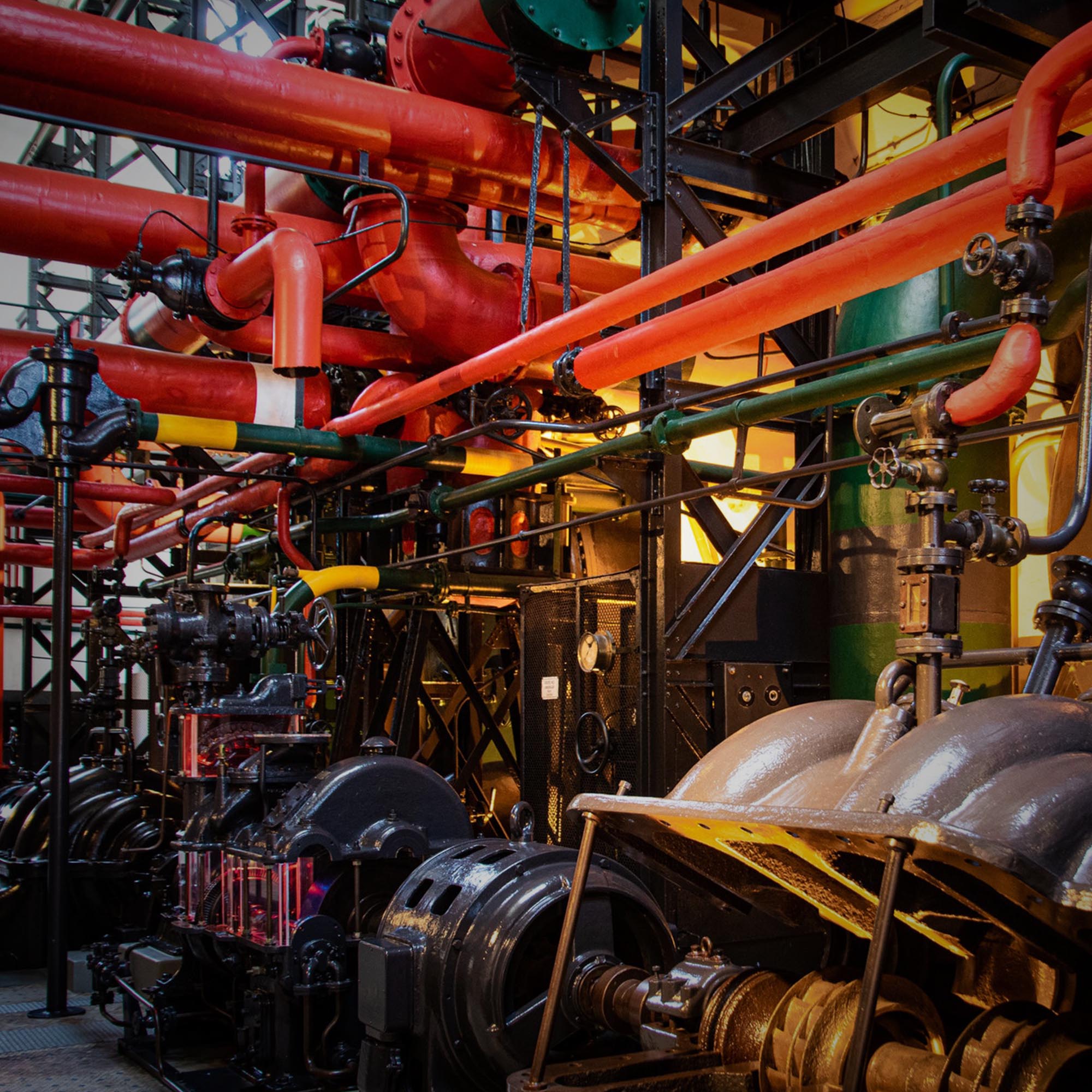

What are o-rings used for?

Their name, as implied, simply refers to a classic doughnut or torus shape, and they exist purely to create a better, more leak-proof seal between two other components, with the aim usually being to prevent the unwanted escape of gases or liquids. Often used in static or dynamic applications, and they enable both linear and rotary movement, making them ideal for hydraulic cylinder pistons or rotating pump shafts.

They are the most common seals used in machinery as they are simple, effective, cost-efficient and have a high resilience to pressure. With a wide variety of sizes available, O-rings are the top choice for most engineers on their mechanical projects.

When do o-rings need replacing?

O-rings need replacing when they show signs of wear, cracking, flattening, or loss of elasticity. This often happens due to prolonged exposure to extreme temperatures, pressure, chemicals, or simply the natural aging of materials. Key indicators that an O-ring may need replacing include leaks, reduced sealing performance, or visible damage. Regular inspection can help catch these signs early, ensuring optimal performance and preventing potential system failures.

Why buy from Totally Seals?

At Totally Seals we offer a wide variety of o-rings, in various materials, sizes and dimensions, whilst we can also produce them in almost any size, material, colour or hardness. Our years of experience, wealth of knowledge and industry connections enable us to supply you with the perfect o-ring for your requirements.

What’s more, if we have the o-rings in stock we offer same day dispatch (before 2pm) and next day delivery (UK) with Global Shipping Options.

Need help with an o-ring?

Let our expert team find the right product for you